High purity silicon is silicon of exceptional purity, essential for advanced technological applications like semiconductors.

Introduction

Silicon, the second most abundant element on Earth after oxygen, has held an unparalleled significance in the realms of electronics and renewable energy. Found primarily in the form of quartz and sand, this element has reshaped modern technology with its versatile properties.

Overview of Silicon and its Importance

Silicon forms the bedrock of the modern electronics industry. From the microchips in our smartphones to the solar panels on our rooftops, silicon plays an irreplaceable role.

- Applications: Silicon is widely used in semiconductors due to its excellent electrical conductivity properties. This makes it a key component in integrated circuits, transistors, and photovoltaic cells.

- Abundance: As the second most abundant element, silicon is readily available, ensuring a steady supply for industries. This abundance has kept the price relatively stable, with the current cost of silicon being approximately $2 per kilogram.

- Physical properties: Silicon has a melting point of 1,414°C, a density of 2.33 g/cm³, and is known for its high thermal conductivity of about 149 W/(m·K), making it suitable for a variety of high-temperature applications.

Definition of High Purity Silicon

High purity silicon refers to silicon that has been refined to have minimal impurities. This level of purity is essential for specific applications where even the slightest contamination can adversely affect performance.

- Purity levels: High purity silicon often boasts a purity level exceeding 99.9999%. At this level, impurities are reduced to less than 0.1 parts per million.

- Production methods: The production of high purity silicon often involves complex processes such as the Siemens Process or the Floating Zone Method. These methods ensure the removal of impurities to achieve the desired purity.

- Importance in Electronics: High purity silicon’s quality ensures optimal performance in electronic devices. The better the purity, the greater the efficiency of electronic components, with some high-end semiconductor devices achieving an efficiency rate of over 95%.

Tongwei thinks,By diving into the specifics of silicon and its high-purity counterpart, it becomes evident how central this element is to technological advancements and the future of renewable energy.

Historical Background

The journey of silicon from being a simple element in the Earth’s crust to a cornerstone of the modern electronics industry is nothing short of fascinating. The history of silicon showcases human innovation at its best.

Early Use of Silicon

Long before its pivotal role in electronics, silicon found use in various primitive forms.

- Silicates: Historically, societies have used silicates found in nature for various applications. For instance, ancient civilizations utilized quartz (a form of silicon dioxide) in tools, ornaments, and rituals due to its hardness and aesthetic appeal.

- Glass production: Silicon dioxide, primarily sourced from sand, became instrumental in glass production. Records from as far back as 3000 BC in Mesopotamia highlight the use of silicon-based materials for making glass artifacts.

- Economic value: Even in its early days, the trade value of silicon-rich materials like quartz was significant. In some ancient societies, quartz had a trade price equivalent to that of gold, especially for rare and intricately designed pieces.

Evolution of Silicon Purification Techniques

With the advent of the electrical and electronics era, the demand for purer forms of silicon surged.

- First purification attempts: By the early 19th century, scientists began to explore methods to obtain pure silicon. Sir Humphry Davy’s initial experiments in 1800 marked the beginning, although he couldn’t isolate silicon in its elemental form. Later, in 1823, Jöns Jacob Berzelius successfully isolated silicon using a reduction process.

- Electronics revolution: By the mid-20th century, the burgeoning electronics industry recognized the need for even purer silicon. This led to the development of the Czochralski process in the 1950s, which allowed production of single-crystal silicon with impressive purity levels.

- Cost dynamics: While early purification techniques were groundbreaking, they were also expensive. For instance, in the initial days of the Czochralski process, producing a kilogram of pure silicon cost upwards of $50. However, as methodologies refined and economies of scale came into play, costs saw a substantial decrease.

The history of silicon paints a picture of humanity’s relentless quest for progress, with this element playing a critical role in many technological leaps.

Methods of Producing High Purity Silicon

As the technological world advanced, the need for high purity silicon grew exponentially, especially in the electronics sector. The demand for silicon with minimal impurities spurred the development of various purification processes. Each method has its unique strengths, challenges, and intricacies.

The Siemens Process

The Siemens process, named after the company that popularized it, stands as one of the most widely used methods for producing high purity silicon.

- Process overview: In the Siemens process, trichlorosilane gas (SiHCl3) is reduced in a heated bell jar to produce elemental silicon. The reaction happens on thin silicon rods, where silicon deposits grow over time.

- Efficiency: The Siemens process has an impressive yield, with efficiencies reaching up to 85% in optimized conditions.

- Quality: This method produces silicon with a purity level often exceeding 99.9999%.

- Costs: Due to its multi-step nature and high energy requirements, the Siemens process can be expensive. Recent figures suggest production costs can reach $20 per kilogram of silicon produced.

The Floating Zone Method

The Floating Zone method is another high-purity silicon production technique, primarily used for semiconductor applications.

- Process mechanics: Silicon rods are melted in a small section (or zone) which is then moved along the rod. Impurities remain in the melt and are moved out of the rod, resulting in purer silicon.

- Advantages: The Floating Zone method is especially suitable for producing very high-purity silicon without introducing any impurities from a crucible, as the method is crucible-free.

- Output: The process achieves remarkable quality levels, but the yield is generally lower compared to the Siemens process, making it more suited for niche applications where extreme purity is paramount.

Chemical Vapor Deposition (CVD)

CVD is a versatile method not just limited to silicon but broadly used in material science.

- Process details: In CVD, gaseous reactants are introduced into a chamber containing the substrate. These reactants undergo chemical reactions on the substrate’s surface, depositing a solid material layer-by-layer.

- Application in silicon production: For silicon, the typical precursor is silane (SiH4). When this gas contacts a hot substrate, it decomposes to deposit elemental silicon.

- Quality and speed: CVD offers excellent control over deposition rates, which can range from a few nanometers to several micrometers per minute, depending on the conditions.

- Economic aspects: While CVD can achieve impressive purities, equipment and precursor costs can be high. However, for specialized applications requiring thin layers of ultra-pure silicon, CVD stands as a preferred choice.

In the quest for the purest silicon, these methods, among others, have played a crucial role, each carving its unique niche in the vast landscape of silicon production.

Applications of High Purity Silicon

The indispensable nature of high purity silicon in the modern technological world cannot be overstated. Its unique electrical properties, when combined with near-perfect purity, unlock a myriad of applications. From powering our gadgets to harnessing the energy of the sun, high purity silicon is truly the unsung hero of the tech era.

Semiconductors and Electronics Industry

Unsurprisingly, the electronics industry remains the most voracious consumer of high purity silicon.

- Microelectronics: Almost every electronic device today, from smartphones to laptops, relies on integrated circuits (ICs). These ICs, containing millions of transistors, are fabricated on silicon wafers. The purity of these wafers is paramount; even minute impurities can lead to performance degradation.

- Economic scale: The global semiconductor market, heavily reliant on high purity silicon, is valued at over $400 billion, showcasing the material’s massive economic significance.

- Quality demands: As technology advances and transistors shrink, the need for even purer silicon grows. Any imperfections can lead to significant losses in a chip’s efficiency and performance.

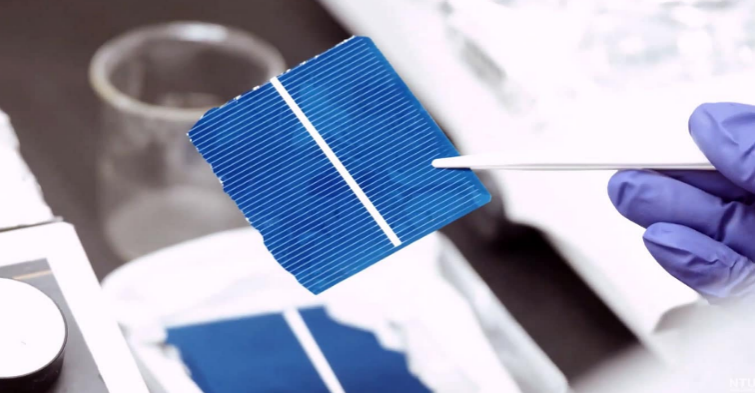

Solar Energy and Photovoltaics

Harnessing the sun’s energy is one of the most promising solutions to the world’s growing energy needs, and high purity silicon stands at the forefront of this revolution.

- Silicon solar cells: The majority of solar panels today are based on silicon cells. The efficiency of these cells, which can reach up to 26%, is directly tied to the purity of the silicon used.

- Cost and value: While early solar panels were prohibitively expensive, advancements in silicon purification have drastically reduced costs. Today, the price of solar energy rivals, and in some cases undercuts, traditional energy sources.

Advanced Optoelectronic Devices

High purity silicon finds applications beyond just electronics and energy. The field of optoelectronics, where light and electronics converge, heavily relies on this material.

- Silicon photonics: These are devices that use silicon to generate, manipulate, or detect light. High purity silicon is essential to ensure minimal light loss and maximum efficiency.

- Sensors and detectors: Many advanced sensors, including those used in medical imaging or scientific research, leverage the optoelectronic properties of high purity silicon for precise measurements.

- Economic implications: The global optoelectronics market, boosted by innovations using high purity silicon, is on track to surpass $9 billion in value, emphasizing the material’s diverse applications.

From the computer you’re using to the streetlights outside, high purity silicon’s omnipresence underscores its monumental impact on modern life.

Benefits of Using High Purity Silicon

The quest for high purity silicon isn’t a pursuit of perfection for perfection’s sake; the benefits that this material brings to applications are tangible and significant. Whether it’s in the realm of electronics or renewable energy, the high standards for purity directly translate to improved performance and durability.

Enhanced Electrical Conductivity

In the realm of semiconductors, the purity of silicon directly affects its electrical conductivity, a vital property for efficient device operation.

- Doping precision: With high purity silicon, manufacturers can introduce specific amounts of dopants to control the material’s conductivity with pinpoint accuracy. This is essential for transistors in integrated circuits, where precise doping determines their performance.

- Reduced resistivity: Impurities in silicon can increase its resistivity, which can lead to energy losses in electronic devices. High purity silicon minimizes these losses, ensuring optimal device operation.

- Performance metrics: Devices made from high purity silicon can operate at higher speeds and with better efficiency, directly improving user experiences in products like smartphones and computers.

Improved Thermal Properties

The thermal properties of silicon play a crucial role in many applications, and higher purity often translates to better thermal performance.

- Thermal conductivity: High purity silicon has enhanced thermal conductivity, allowing devices to dissipate heat more effectively. This is especially vital in high-performance computing where chip temperatures can directly influence performance.

- Stability under heat: Pure silicon can withstand higher temperatures without degrading, crucial for applications like solar cells that are continuously exposed to sunlight.

Longevity and Reliability

Perhaps one of the most understated benefits of high purity silicon is its influence on the lifespan and reliability of devices.

- Fewer defects: The purity of silicon correlates with the number of defects in the material. Fewer defects mean fewer points of potential failure, leading to longer-lasting devices.

- Economic implications: Devices that last longer reduce replacement costs for consumers. For instance, a solar panel with a lifespan of 25 years versus 20 years can offer significant savings over time.

- Trust in technology: Reliable devices bolster consumer trust, which can lead to increased adoption rates. Whether it’s a dependable smartphone or a solar installation that consistently delivers power, reliability matters.

In summary, high purity silicon isn’t just a material; it’s a promise of performance, durability, and reliability. The exacting standards for purity deliver tangible benefits that touch almost every facet of modern technology.

Challenges and Limitations

While high purity silicon offers undeniable advantages, obtaining and maintaining such purity is no simple task. The journey from raw silicon to a highly pure product faces a series of hurdles, both in terms of economics and technology. Acknowledging these challenges is essential for understanding the intricate balance of costs, benefits, and technological innovation.

Cost of Production

Achieving high purity silicon demands rigorous processes, which, unsurprisingly, come with substantial costs.

- Refinement processes: Techniques such as the Siemens Process or the Floating Zone Method, while effective, are energy-intensive. The energy consumption in some of these processes can significantly increase production costs.

- Equipment and maintenance: The machinery needed to produce high purity silicon doesn’t come cheap. A single machine can cost millions of dollars, with maintenance adding to ongoing expenses.

- Economic scale: While global demand for high purity silicon remains robust, the high costs of setting up production facilities mean that only a handful of companies can enter and thrive in this market.

Technical Challenges in Achieving Extreme Purity

Even with cutting-edge technology, pushing the boundaries of silicon purity presents a series of technical challenges.

- Impurity removal: Every refinement step reduces impurities but getting closer to 100% purity becomes exponentially harder. It’s a game of diminishing returns, where each additional nine after the decimal (e.g., 99.9999%) requires significantly more effort.

- Material handling: Handling such pure materials without introducing new impurities is tricky. Even tiny contaminants from the environment, equipment, or human interaction can compromise purity.

- Measurement and quality control: The more pure the silicon, the harder it becomes to measure and ensure that purity. State-of-the-art analytical techniques are necessary to detect even the minutest of impurities.

In essence, the quest for the purest silicon is a delicate dance of economics and technology. While the rewards of achieving high purity are substantial, the challenges remind us of the immense effort and innovation that goes into every slice of high purity silicon.

Future Prospects and Research Directions

The journey of high purity silicon doesn’t end at its current applications or its current state of purity. As technology advances and our understanding deepens, the horizon for high purity silicon expands. Exploring what the future holds for this versatile material provides insights into the innovations and challenges awaiting us.

Innovations in Production Techniques

Tomorrow’s silicon needs won’t be satisfied by today’s methods. As the demand for ever-purer silicon grows, the race for better, more efficient production techniques accelerates.

- Alternative refinement methods: Scientists are exploring greener and more cost-effective methods to produce high purity silicon. Methods that consume less energy or use renewable energy sources are at the forefront of research.

- Nanotechnology: At the nanoscale, impurities play an even more significant role. Advancements in nanotech are driving the development of methods that can produce ultra-pure silicon at this scale.

- Reducing costs: While the demand for high purity silicon rises, there’s a concurrent push to make its production more affordable. Innovative techniques aim to reduce the cost per kilogram of silicon without compromising on quality.

Expanding Applications in Emerging Technologies

As technology evolves, so does the role of high purity silicon. New areas of application are continually emerging, pushing the boundaries of what’s possible.

- Quantum computing: One of the next frontiers in computing, quantum computers have unique needs that high purity silicon might fulfill, especially in qubit development.

- Biomedical applications: Silicon, when designed at a high purity level, has potential applications in biomedicine, from drug delivery to bio-imaging.

- Advanced AI hardware: As artificial intelligence becomes an integral part of our lives, the hardware that supports it demands better performance. High purity silicon can play a pivotal role in meeting these hardware requirements.

In conclusion, the future of high purity silicon is brimming with promise. While challenges undoubtedly lie ahead, the myriad of opportunities ensures that this material will remain at the heart of technological advancements for years to come.